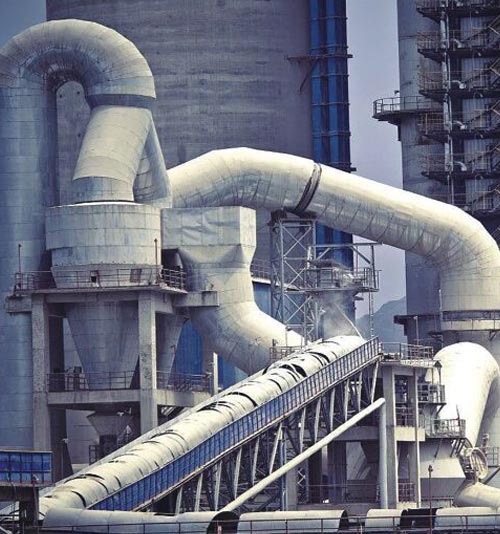

Cement industry/lime kiln

The cement raw meal does not completely decompose CACO3 dust in the decomposition furnace, and CACO produces CaO dust during the decomposition process;

SO, NO, CO, CO2 and other gases produced during the combustion process of calcined pulverized coal;

The temperature of the kiln tail exhaust gas coming out of the cyclone reaches above 320°C, and the gas is dry;

The smoke concentration reaches 40-130 mg/Nm3, and more than 90% of the dust particles have a particle size less than 1 μm;

The CO and CO2 contents sometimes fluctuate depending on the combustion adequacy of pulverized coal.

Cement kiln head: high concentration of smoke and dust, strong grinding ability, high temperature and high humidity. Cement kiln tail: fine dust, difficult to capture, sticky and sticky, difficult to clean, high temperature, easy to fluctuate, the following products are recommended

| product code | processing method | fabric structure | Weight(g/㎡) | Breathability cm³/cm² *S | Combustible content | Tensile strength | Recommended temperature | |

| vertical | latitudinal | |||||||

| B-01PF | PETF treatment + lamination | double twill | 750±25 | 2-5 | >10 | >2400 | >2000 | ≤260 |

| B-03NF | Anti-acid treatment film | 1/3Twill | 340±15 | 2-5 | >10 | >1300 | >800 | ≤260 |

The selection of filter cloth also needs to be based on the particle size, density, chemical composition and filtration process conditions of the slurry. Due to the different materials and methods of weaving filter cloth, its strength, elongation, air permeability, thickness, etc. are different, which affects the filtration effect.

The filter bag manufacturer introduces the types of filter cloth to you. According to the weaving method, there are monofilament filter cloth, including single multifilament filter cloth, multifilament filter cloth, double-layer filter cloth, non-woven filter cloth, and industrial filter belt.

① Monofilament filter cloth: The filter cloth has a smooth surface and excellent dehydration properties, ensuring that the filter cake is easy to peel off and easy to regenerate. It is suitable for filter presses, leaf filters and all continuously working filtration equipment.

②Multifilament filter cloth: suitable for filtration and separation of very fine particles. Its wear resistance is not as good as that of monofilament filter. It is mainly used in filter presses, centrifuges, drum machines, etc.

③Double-layer filter cloth: This high-strength filter cloth with good liquid drainage function is specially designed for vacuum belt filters, vacuum drum filters, centrifuges and other equipment, and has excellent dehydration performance.

④ Non-woven filter cloth: suitable for ultra-fine particle filtration and flue gas dust removal in ceramics and other industries.

⑤Industrial filter belt: suitable for gypsum dehydration in power plants, sewage treatment, starch sugar filtration, pharmaceuticals, brewing, food and beverage and other industries.

RELATED

RELATED

RELATED

RELATED